Solidworks Drawing Slot Callout

- Hole callouts are available in drawings. If you change a hole dimension in the model, the callout updates automatically. Hole callouts use Hole Wizard information when you create a hole with the Hole Wizard. The default formats for the Hole Wizard types are stored in solidworkslangcalloutformat.txt.

- Learn how to create hole callouts that will automatically insert useful information in SOLIDWORKS Drawings. We will also look at a way to troubleshoot hole c.

- Predefine the slot information that you want to retrieve into the callout using the Dimension Style dialog box, and modify the callout information using the Callout Properties dialog box. Use the same property text codes for simple slots and counterbore slots as you do for holes to extract the size and depth information into a drawing callout.

One frequent comment I hear about model-based definition (MBD) is that the graphics views are crowded with 3D annotations. In this article, let’s walk through two examples of MBD and see how you can reduce the number of annotations.

The first example is a lathe collet chuck as shown in Figure 1. Typically, a collet holds tightly to a part being machined by a lathe cutter while the part is turning at several thousand rounds per minute (RPM).

SolidWorks 2009 provides improved drawing performance by allowing you to choose which drawing sheet or sheets to load when opening a drawing. Slot Detailing (1m:29s) You can now insert center marks in slots, include slots in hole tables, and display hole callouts for straight slots. This is a 'Wheel Project' video and intended to be used to learn SolidWorks as a beginning student. Tags for this should be: Education, SolidWorks, Tutorial, 3D Modeling, Technical Drawing.

Figure 1. A lathe (top), a chuck (lower left) and a collet (lower right).

Figure 2 shows a collet with 3D annotations in SOLIDWORKS MBD. As you can see, the gaps are all of the same width and tolerance, but the repetitive instances make the display crowded.

Figure 2. A collet with crowded repetitive 3D annotations.

Wouldn’t it be nice if we could group all the instances and call them out together with one annotation? Here is one function that can help with this process.

First, click on the Pattern Feature command on the SOLIDWORKS MBD command bar as shown in Figure 3.

Figure 3. Click on the Pattern Feature command.

Second, select “Manual Patterns” on the property manager on the left of the display as shown in Figure 4.

Figure 4. Select “Manual Patterns” to create a pattern.

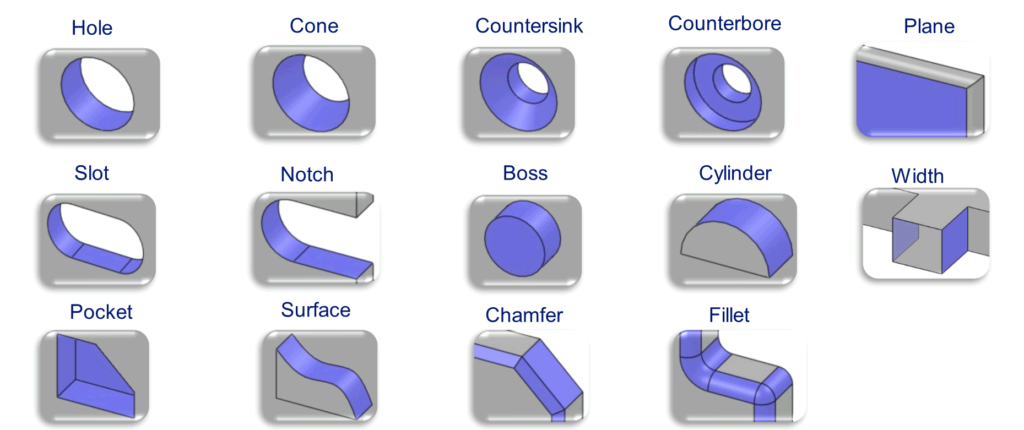

Then select the features to be defined in this manual pattern. In this case, let’s group all the gaps, or the width features, in the Geometric Dimensioning and Tolerancing (GD&T) terms. Pick one face of a gap, and then select “Create Width Feature” on the context dialog as shown in Figure 5.

Figure 5. Pick one face of a gap, and then select “Create Width Feature”.

Then click on the opposing face of the same gap to create a width feature as one instance in this pattern.

Figure 6. Select the opposing face of the same gap to create a width feature.

Then repeat the same operation for all the other gaps. Figure 7 shows all eight of the width features collected in one manual pattern.

Figure 7. Define all the width features in a manual pattern.

These width feature and pattern creation steps can be a bit tedious. It would be great if the software were able to recognize all the gaps and create all eight width features automatically. Furthermore, when you select an opposing face, you have to rotate the model to click the face. It would be very handy if you could just pick an edge to represent a face without rotating the model. Then the software could create a width feature from the opposing faces. Today, hole callouts and location dimensions support multiple edge selections to represent faces. This edge-face correlation needs to be expanded to width features.

Now with the setup in place, use the Size Dimension to call out this width feature pattern as shown in Figure 8. You have the option of calling out one width feature as selected, or the entire pattern. Please select the pattern to simplify the callouts.

Figure 8. Call out a width feature pattern with an 8x multiplier.

Figure 9 shows a before and after comparison. As you can see, the display is much more concise with the manual width feature pattern and the 8x multiplier. Furthermore, with all of the instances cross-highlighted, the interpretation is well facilitated visually.

Figure 9. A before and after comparison of 3D annotations.

In addition to the manual patterns avoiding repetitive callouts, SOLIDWORKS MBD can also combine multiple callouts into a compact parent feature callout. Let’s look into a base plate example as shown in Figure 10, which illustrates the overlapping callouts of multiple countersink holes and counter bore holes in the lower right corner.

Dimensioning Slots In Solidworks

Figure 10. Overlapping callouts of multiple features.

How can this view be cleaned up? A previous blog post shared several view management tools to help organize and present 3D annotations clearly, but in this article, we will try several different annotation techniques.

First of all, the reason that the annotations in the lower right corner of Figure 10look so busy is that the counter bore holes and countersink holes are complex features. Each of these features includes several child features that require individual specifications, such as the drill diameters, counterbore diameters, counterbore depths and countersink angles. Using SOLIDWORKS MBD, you can actually combine these child feature callouts into one single parent feature callout. Figure 11 shows a context menu command “Combine Callout Dimension,” which appears when you right-click on one of the child feature callouts.

Figure 11. Combine all the child feature callouts into a parent counterbore feature.

In the case of Figure 11, I clicked on a depth. Then the software automatically collected all the child feature callouts and presented one single compact callout as shown in Figure 12. It combined the drill diameters and tolerances, counterbore diameters and tolerances, overall hole depths and tolerances, and counterbore depths and tolerances. This compact presentation with a special counterbore designation saved multiple annotations, dimension lines and witness lines.

Figure 12. A compact counterbore hole callout.

Similarly, I right-click on the countersink angle callout and picked “Combine Callout Dimensions” as shown in Figure 13.

Figure 13. Combine all the child feature callouts into a parent countersink feature.

Then a compact callout including a special countersink designation will be presented as shown in Figure 14. All the drill diameters and tolerances, countersink diameters and tolerances, countersink angles and tolerance are collected in one annotation.

Solidworks Threaded Hole Callout

Figure 14. A compact countersink hole callout

Figure 15 shows a before and after comparison. Clearly, the results are much cleaner now.

Figure 15. A before and after comparison of 3D annotations.

By the way, the base plate model is available for download at the National Institute of Standards and Technology (NIST). Please feel free to try it out yourself. To learn more about how SOLIDWORKS MBD can help with your MBD initiatives, please visit its product page.

About the Author

Hole Thread Callout Solidworks Drawing

Oboe Wu is a SOLIDWORKS MBD product manager with 20 years of experience in engineering and software. He is an advocate of model-based enterprise and smart manufacturing.